If you’re in the process of building or renovating a structure that includes masonry openings, it’s crucial to understand the importance of using the correct steel lintel sizes. These sturdy structural components play a vital role in supporting the weight of the masonry above them, ensuring the integrity and stability of the entire structure.

In this article, we will provide an overview of steel lintel sizes for masonry openings, guiding you through the key considerations to help you make informed decisions for your construction project. So let’s dive in and explore the world of steel lintels!

Importance of Steel Lintels in Masonry Openings

When it comes to constructing buildings with masonry walls, steel lintels play a critical role. These horizontal structural components provide essential support, prevent cracking and sagging, and allow for larger openings. Understanding the importance of steel lintels in masonry openings is crucial in ensuring the durability and stability of a building.

Provides Structural Support

One of the primary purposes of steel lintels is to provide structural support to masonry openings such as windows and doors. As masonry walls are not typically load-bearing, a steel lintel is installed above the opening to bear the weight of the wall above it. Without a properly sized and installed steel lintel, the masonry wall could crack or sag under the load, compromising the structural integrity of the entire building.

Prevents Cracking and Sagging

Cracks in masonry walls can occur when the weight of the wall above an opening is not adequately supported. By distributing the load evenly across the lintel, steel lintels prevent cracking and sagging. This ensures that the masonry opening remains stable and intact, reducing the risk of significant structural damage over time.

Allows for Larger Openings

Steel lintels allow for the creation of larger openings in masonry walls, which can enhance the aesthetic appeal of a building and provide more natural light and ventilation. By providing additional support and distributing the weight of the wall, steel lintels enable architects and designers to incorporate expansive windows and doors into their structures without compromising their stability.

Factors to Consider When Selecting Steel Lintel Sizes

Selecting the correct size of a steel lintel is crucial to ensuring its effectiveness and the overall structural integrity of the building. Several factors must be taken into consideration when determining the appropriate steel lintel size for a masonry opening.

Load-Bearing Capacity

The load-bearing capacity of a steel lintel refers to its ability to support the weight of the masonry wall above it without deforming or failing. It is important to calculate the total load that the lintel will bear, including the weight of the wall and any additional loads such as wind or snow. Selecting a steel lintel with a sufficient load-bearing capacity is vital to prevent overloading and potential structural failure.

Span Length

The span length of a steel lintel refers to the distance between the supports on either side of the opening. The longer the span length, the greater the load that the lintel must bear. It is essential to accurately measure the span length and select a steel lintel that can safely support the anticipated load across the distance. Ignoring span length limits can lead to deflection or collapse of the lintel and compromise the stability of the masonry opening.

Masonry Type

Different types of masonry, such as brick or concrete block, have different characteristics and require unique considerations when selecting a steel lintel. The weight and density of the masonry, as well as the method of construction, can impact the size and load-bearing capacity required of the steel lintel. It is crucial to consult with experts or structural engineers who are knowledgeable about the specific masonry type to determine the appropriate lintel size.

Building Codes and Regulations

Building codes and regulations exist to ensure the safety and structural integrity of buildings. They often specify requirements for steel lintel sizes based on factors such as load-bearing capacity, span length, and masonry type. It is essential to comply with these codes and regulations when selecting steel lintels to avoid potential legal issues and ensure the structural stability of the building.

Standard Sizes of Steel Lintels for Masonry Openings

Steel lintels come in a range of standard sizes to accommodate various masonry openings and construction requirements. Understanding these standard sizes can help in the selection process and simplify the overall construction process.

Common Widths and Depths

Standard widths of steel lintels typically range from 3 inches to 12 inches, depending on the load-bearing requirements. The depth of steel lintels generally ranges from 2 inches to 8 inches, depending on the thickness of the masonry wall and load-bearing calculations. It is important to choose a width and depth that can adequately support the anticipated load without compromising the structural integrity of the masonry opening.

Available Lengths | Lintel Sizes for Masonry Openings

Steel lintels are typically available in standard lengths ranging from 3 feet to 12 feet. However, longer custom lengths can be ordered for specific project requirements. It is crucial to accurately measure the width of the opening to ensure the lintel is correctly sized and provides adequate support. If necessary, multiple steel lintels can be combined to cover a larger opening and distribute the load more evenly.

Calculating the Correct Steel Lintel Size

Calculating the correct size of a steel lintel involves several steps to ensure optimal structural support and prevent potential failure.

Determining the Load

To calculate the load that a steel lintel will bear, it is essential to consider the total weight of the masonry wall above the opening. This includes the weight of the masonry units, any additional loads such as wind or snow, and any point loads such as roof trusses bearing on the wall. Consulting a structural engineer or using load calculation software can help accurately determine the expected load on the lintel.

Estimating the Span Length

Measuring the span length accurately is crucial in selecting the correct steel lintel size. The span length refers to the distance between the supports on either side of the opening. It is important to measure this distance precisely to avoid underestimating or overestimating the required lintel size. If in doubt, consulting a structural engineer can provide expert guidance in estimating the span length.

Consulting Structural Engineers

While it is possible to make initial calculations for steel lintel sizes based on load and span length, it is always recommended to consult with a structural engineer. These professionals have the expertise and knowledge to accurately evaluate the specific requirements of a project and determine the most suitable steel lintel size. Their expertise ensures that the selected lintel can safely bear the anticipated load, comply with building codes and regulations, and maintain the structural integrity of the masonry opening.

Common Types of Steel Lintels

Different types of steel lintels are available to suit specific masonry opening requirements and construction needs. Understanding the characteristics and advantages of each type can help in selecting the most suitable steel lintel for a particular project.

Angle Lintels

Angle lintels, also known as L-shaped lintels, are a common type of steel lintel used in masonry construction. These lintels have a 90-degree angle and are often used for openings in brick or block walls. Angle lintels provide strong structural support and distribute the load evenly across the masonry opening. They are versatile, cost-effective, and readily available in various standard sizes.

Channel Lintels

Channel lintels, also known as C-section lintels, have a U-shaped profile with two flanges and a central web. These lintels are commonly used in commercial and industrial construction due to their exceptional load-bearing capacity. Channel lintels are highly versatile and can be easily installed by securing them to the masonry with appropriate fixings. They are available in a range of standard sizes to accommodate different masonry opening requirements.

Box Lintels

Box lintels, also known as flat plate lintels, are rectangular steel lintels with equal flanges on the top and bottom. These lintels offer excellent load-bearing capacity and are suitable for openings in larger masonry walls. Box lintels can be easily installed and often used in situations where aesthetics or architectural design considerations are important. They can be customized to specific project requirements and are available in various sizes to accommodate different load-bearing needs.

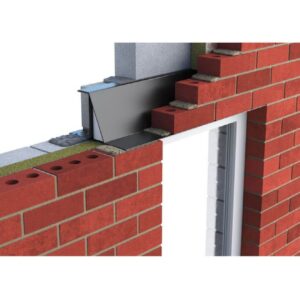

Installation Guidelines for Steel Lintels

Proper installation of steel lintels is crucial to ensure their effectiveness and the long-term stability of the masonry opening. Following these installation guidelines can help achieve a successful and reliable outcome.

Preparing the Masonry Opening

Before installing a steel lintel, the masonry opening must be properly prepared. This involves removing any loose or damaged masonry, ensuring a clean and level surface for the lintel to rest on. It is important to carefully measure the width and height of the opening to ensure the lintel is correctly sized. Additionally, any necessary adjustments or reinforcements should be made to the masonry supports to accommodate the desired lintel installation.

Placing the Steel Lintel

Once the masonry opening is prepared, the steel lintel can be placed into position. It is essential to ensure that the lintel is level and correctly aligned with the masonry supports on either side of the opening. The lintel should fit snugly into the opening without any gaps or interference. If necessary, shims or spacers can be used to provide additional support and maintain the proper alignment.

Fixing and Securing the Lintel

To secure the steel lintel in place, appropriate fixings should be used. This can include using masonry anchors, screws, or bolts depending on the construction requirements and load-bearing needs. It is essential to follow the manufacturer’s instructions and guidelines for the specific fixings to ensure secure and reliable attachment. Properly securing the lintel prevents any movement or displacement, ensuring its structural integrity and the stability of the masonry opening.

Maintenance and Inspection of Steel Lintels

Regular maintenance and inspection of steel lintels are crucial to identify and address any potential issues promptly. This helps maintain their effectiveness and extend their lifespan.

Checking for Corrosion

One of the primary maintenance tasks for steel lintels is checking for corrosion, especially in areas with high humidity or exposure to saltwater. Corrosion can weaken the steel lintel over time, compromising its load-bearing capacity and structural integrity. Regular inspections should be conducted to identify any signs of rust or deterioration. If corrosion is detected, appropriate steps should be taken to clean, repair, or replace the affected lintels to ensure their continued functionality and safety.

Repairing or Replacing Damaged Lintels

In the event of damage or failure, steel lintels may need to be repaired or replaced. It is crucial to address any issues promptly to prevent further deterioration or structural damage to the masonry opening. This may involve applying appropriate coatings or sealants to protect against corrosion, reinforcing or strengthening the lintel, or completely replacing it if necessary. Consulting with experts or structural engineers is recommended to determine the most suitable course of action for damaged steel lintels.

Common Mistakes to Avoid When Choosing Steel Lintel Sizes

Selecting the correct size of steel lintels is essential to ensure optimal performance and avoid potential structural failures. Avoiding these common mistakes can help in choosing the right lintels for masonry openings.

Underestimating Load Capacity

Underestimating the load capacity of a steel lintel can result in overloading and potential failure. It is crucial to accurately calculate the total load that the lintel will bear, including all potential loads and point loads. Consulting with structural engineers or using load calculation software can help ensure accurate load capacity calculations and prevent underestimation.

Ignoring Span Length Limits

Ignoring span length limits can lead to deflection, sagging, or collapse of the steel lintel and compromise the stability of the masonry opening. It is important to measure the span length accurately and select a lintel that can safely support the anticipated load across the distance. Ignoring span length limits can result in an inadequate lintel size and potential structural issues.

Not Complying with Building Codes

Building codes and regulations provide guidelines and requirements for steel lintel sizes to ensure the safety and structural integrity of buildings. Failing to comply with these codes can result in legal issues, as well as potential structural failures. It is essential to consult and adhere to the relevant building codes and regulations when selecting and installing steel lintels to ensure proper compliance and safety.

Benefits of Custom Steel Lintels

While standard sizes of steel lintels are readily available, opting for custom-made lintels can offer a range of benefits for specific project requirements.

Tailored to Specific Project Requirements

Custom steel lintels allow for precise tailoring to the specific needs of a project. This includes accommodating unique masonry opening sizes, load-bearing capacities, and architectural design considerations. By customizing the lintels, it is possible to achieve optimal performance and structural stability, ensuring the long-term success of the building project.

Allows for Unique Design Features

Custom steel lintels provide the opportunity to incorporate unique design features into a building. This includes customized shapes, profiles, or finishes that enhance the aesthetic appeal of the masonry openings. Custom lintels can be designed to complement the overall architectural design concept and create a distinctive visual impact.

Conclusion

Steel lintels are essential components in masonry openings, providing structural support, preventing cracking and sagging, and allowing for larger openings. When selecting steel lintels, factors such as load-bearing capacity, span length, masonry type, and compliance with building codes should be considered. Standard sizes of steel lintels are available, but customization allows for tailored lintels that meet specific project requirements and design features.

Proper installation, maintenance, and inspection of steel lintels are crucial to ensuring their effectiveness and longevity. By avoiding common mistakes and following installation guidelines, the structural integrity of the masonry opening can be maintained. Regular maintenance, including checking for corrosion and repairing or replacing damaged lintels, will help extend their lifespan.

In conclusion, understanding the importance of steel lintels, selecting the correct size, and following proper installation and maintenance practices are essential for masonry construction projects. With the right steel lintels in place, buildings can enjoy long-lasting stability and structural integrity.