Are you curious about whether gravel can be used as aggregate? Look no further, because this article will provide you with all the information you need. Gravel is a commonly found material and many wonder if it can be used as aggregate in various construction projects. By the end of this article, you will have a clear understanding of whether or not gravel can serve as a suitable alternative for aggregate.

What is Gravel?

Definition of Gravel

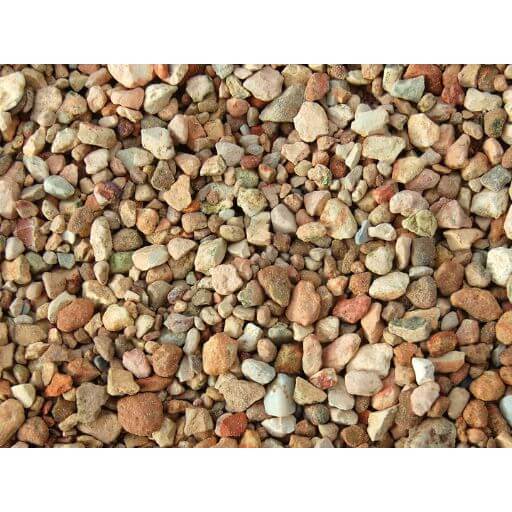

Gravel is a loose aggregation of small rock fragments, commonly formed by the natural erosion of larger rocks. It is often composed of a mixture of different-sized particles, ranging from pebbles to small stones and can be found in various colors and textures. Gravel is commonly used in construction and landscaping due to its versatility and durability.

Types of Gravel

There are several types of gravel available, each with its own unique characteristics and uses. Some common types of gravel include:

- Pea Gravel: Pea gravel consists of small, smooth, and rounded stones that are typically between 1/8 to 3/8 inch in size. It is commonly used for decorative purposes, such as in garden paths or as a mulch replacement.

- Crushed Stone: Crushed stone is a form of gravel that is mechanically crushed for various construction purposes. It is available in different sizes, from coarse to fine, and is often used as a base material for driveways, roads, and concrete production.

- Bank Gravel: Bank gravel is a naturally occurring gravel that is typically found in river beds or banks. It is often used for drainage systems, as backfill, or in the construction of roads and driveways.

- Graded Aggregate Base: Graded aggregate base (GAB) is a mixture of various sizes of gravel and sand. It is commonly used as a base layer in road construction or as a foundation for buildings.

- Crushed Granite Gravel: Crushed granite gravel is made from granite rocks that have been crushed and screened to a specific size. It is commonly used as a decorative material in landscaping projects or as a base material for walkways and patios.

What is Aggregate?

Definition of Aggregate

Aggregate is a broad term that refers to a mixture of various particles, such as gravel, sand, crushed stone, or recycled concrete. It is used in construction projects to create solid foundations, provide structural support, and enhance the durability of structures.

Types of Aggregate

Just like gravel, there are different types of aggregate that are commonly used in construction:

- Coarse Aggregate: Coarse aggregate refers to larger-sized particles, typically greater than 4.75 mm in diameter. It can include gravel, crushed stone, or large rocks. Coarse aggregate is commonly used in concrete production, road construction, and drainage systems.

- Fine Aggregate: Fine aggregate consists of smaller-sized particles, typically less than 4.75 mm in diameter. It can include sand, crushed stone dust, or recycled materials. Fine aggregate is commonly used in mortar, plastering, and concrete production.

Similarities Between Gravel and Aggregate

Composition

Both gravel and aggregate are composed of various types and sizes of particles. They can both include gravel, crushed stone, and other materials.

Uses

Gravel and aggregate are widely used in construction and landscaping projects. They are used for purposes such as road construction, concrete production, and drainage systems. Both materials provide stability, strength, and durability to structures.

Differences Between Gravel and Aggregate

Size

Gravel typically refers to particles ranging from about 2 to 64 mm in size, while aggregate can encompass a wider range of particle sizes.

Shape

Gravel particles are often irregular and less uniform in shape compared to aggregate particles, which can have various shapes depending on the source material.

Source

Gravel is commonly derived from natural sources, such as rivers, while aggregate can be sourced from natural or processed materials, including rocks, sand, or recycled concrete.

Manufacturing Process

Gravel is often produced through natural erosion and weathering of larger rocks, while aggregate can be manufactured through crushing, screening, and grading processes.

Can Gravel be Used as Aggregate?

Pros of Using Gravel as Aggregate

- Cost-effective: Gravel is often cheaper than other types of aggregate, making it an attractive option for budget-conscious projects.

- Natural Appearance: Gravel can provide a natural and aesthetically pleasing look in landscaping projects or as a decorative material.

- Local Availability: Gravel is commonly found in many regions, making it easily accessible for use as aggregate.

Cons of Using Gravel as Aggregate

- Size Variation: Gravel particles vary in size, which can impact the consistency and workability of concrete mixes or other construction applications.

- Limited Application: Gravel may not be suitable for all construction purposes, especially those that require specific particle sizes or shapes.

- Durability: Gravel may be less resistant to wear and tear compared to some other types of aggregates, potentially affecting the longevity of structures.

Considerations for Using Gravel as Aggregate

- Project Requirements: Evaluate whether the properties of gravel, such as particle size and shape, align with the specific requirements of the construction project.

- Quality Control: Implement rigorous quality control measures to ensure that the gravel used as aggregate meets the necessary standards and specifications.

Take a look at more Decorative Aggregate Reviews

Applications of Gravel as Aggregate

Road Construction

Gravel is commonly used as a base layer for roads and highways due to its stability, drainage properties, and ability to withstand heavy loads. It provides a solid foundation and helps to distribute the weight of vehicles, preventing the deformation of the road surface.

Concrete Production

Gravel can also be used as a primary component in concrete production. It provides strength and stability to the concrete mixture, acting as the coarse aggregate. The size and shape of the gravel particles can influence the workability and strength of the concrete mix.

Drainage Systems

Gravel is frequently used in the construction of drainage systems, including French drains and septic fields. Its porous nature allows water to pass through, preventing water buildup and potential damage to structures.

Preparation and Quality Assessment

Grading and Separation

Before using gravel as aggregate, it is important to properly grade and separate the particles to ensure uniformity and consistency. This can be done through mechanical processes such as sieving and screening.

Particle Shape Analysis

The shape of gravel particles can impact the performance of the aggregate in construction applications. Particle shape analysis, which may involve visual inspection or laboratory testing, can be used to assess the shape characteristics of the gravel.

Quality Testing

To ensure the quality and suitability of gravel as aggregate, various tests can be conducted, including particle size distribution analysis, bulk density measurement, and crushing strength evaluation. These tests help determine if the gravel meets the required specifications and standards.

Alternatives to Gravel as Aggregate

Crushed Stone

Crushed stone is a commonly used alternative to gravel. It is mechanically crushed and can be sourced from various rocks, such as granite or limestone. Crushed stone offers similar benefits to gravel in terms of strength, stability, and durability.

Sand

Sand is another alternative to gravel as an aggregate. It is finely divided particles that are commonly used in concrete and mortar mixes. Sand is available in different grades, depending on the size of the particles, and provides good workability and compressive strength to building materials.

Recycled Concrete

Recycled concrete, obtained from crushing and processing old concrete structures, can also be used as an alternative to gravel as aggregate. It helps reduce waste and conserve natural resources while providing similar properties to traditional aggregates.

Read reviews on the Best Cement

Environmental Impact of Gravel as Aggregate

Extraction and Habitat Destruction

The extraction of gravel from natural sources can lead to habitat destruction and disruption of ecosystems. It is important to implement sustainable extraction practices and minimize the environmental impact.

Water Pollution

Runoff from gravel mining sites can carry sediment and pollutants into nearby water bodies, affecting water quality and aquatic ecosystems. Proper erosion control measures should be implemented to prevent water pollution.

Air Pollution

Dust emissions during gravel extraction and processing can contribute to air pollution. Implementing dust control measures, such as water spraying or dust suppression systems, can help minimize air pollution.

Conclusion

Gravel and aggregate play crucial roles in various construction and landscaping projects. While they are similar in many aspects, such as composition and uses, there are also notable differences between them. Gravel can be used as aggregate, but careful considerations and quality assessment are necessary to ensure its suitability for specific applications. Alternatives such as crushed stone, sand, and recycled concrete can also be utilized based on project requirements and environmental considerations. By understanding the characteristics, uses, and environmental impacts of gravel and aggregate, you can make informed decisions in your construction endeavors.