If you’re in the construction industry or planning to undertake a building project, understanding the various steel lintel sizes available is crucial. Steel lintels serve a critical role in providing structural support and stability to the load-bearing walls of a building. In this article, we will explore the different sizes of steel lintels, helping you make informed decisions for your construction needs. From small residential projects to large commercial developments, let’s dive into the world of steel lintel sizes and discover how they can enhance your construction projects.

1. What are steel lintels?

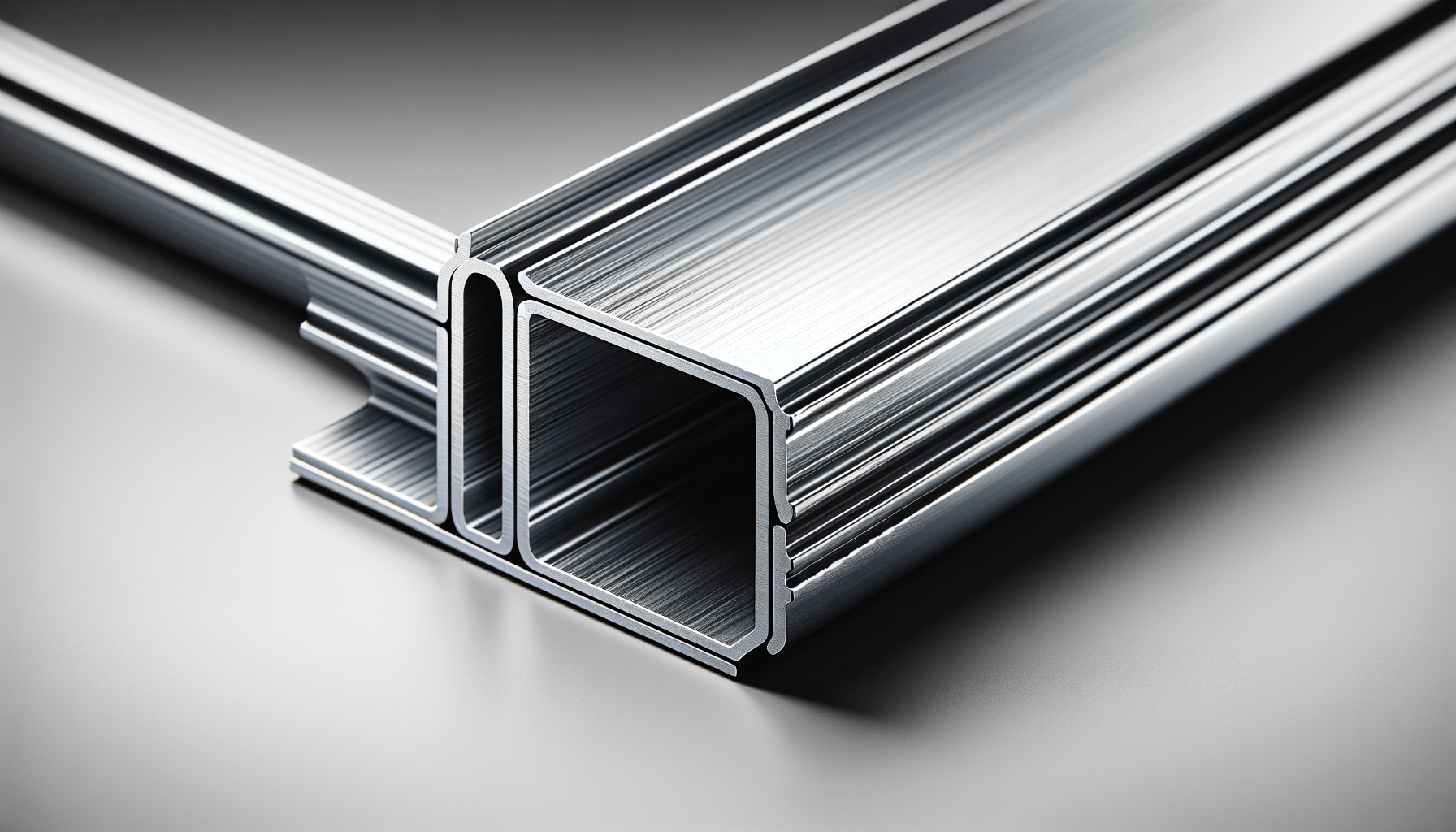

Definition of steel lintels

Steel lintels are structural components commonly used in construction. They are horizontal beams made of steel and are designed to support the load above an opening, such as a door or window, in a building. These lintels distribute the weight evenly and prevent the building from collapsing.

Importance of steel lintels in construction

Steel lintels play a crucial role in the integrity and stability of a building. They provide support and prevent the walls from sagging or buckling under the weight of the structure above the opening. By distributing the load efficiently, steel lintels help maintain the structural integrity of the building and ensure its long-term durability. They are essential for maintaining the overall strength and stability of a structure by effectively transferring the load to the surrounding walls or columns.

2. Factors influencing steel lintel sizes

Load-bearing capacity

The load-bearing capacity of a steel lintel is one of the primary factors determining its size. The lintel must be able to support the weight of the structure above the opening without any deformation or excessive deflection. The load-bearing capacity should be calculated based on the maximum expected load, including the weight of the materials being supported and any additional live loads such as wind or snow.

Span length

The span length, or the distance between the two supporting points, also plays a crucial role in determining the size of the steel lintel. Longer spans require larger and stronger lintels to ensure sufficient support and prevent any structural issues. The span length is typically measured from the inner face of the supporting walls or columns.

Building regulations and standards

Building regulations and standards provide guidelines on the minimum requirements for steel lintel sizes based on the specific application, structural design, and region. Compliance with these regulations ensures that the lintels meet the necessary safety and structural integrity standards. It is essential to consult the relevant building codes and standards to determine the minimum requirements for steel lintel sizes in a particular area.

Type of construction

The type of construction, whether it is a residential, commercial, or industrial building, can also influence the size of the steel lintels. Different building types have varying load requirements and design considerations, which may affect the sizing of the lintels. For example, commercial buildings often have larger openings and higher load requirements compared to residential structures.

Building design

The overall design of the building, including architectural features, can impact the size of the steel lintels. If the building design includes large windows or glass facades, the lintels need to be resized accordingly to provide adequate support while maintaining an aesthetically pleasing appearance. The design considerations should be carefully evaluated to ensure that the steel lintels meet both structural and architectural requirements.

3. Standard steel lintel sizes

Common sizes available in the market

Standard steel lintels are available in a range of sizes to accommodate different applications and structural requirements. The market offers various common sizes, including 100mm, 140mm, 150mm, 200mm, and 250mm, among others. These sizes are commonly used in residential and commercial construction projects.

Typical dimensions and profiles

Standard steel lintels usually have a rectangular or “I” shaped cross-section. The dimensions of the lintels vary depending on the required load-bearing capacity and span length. The depth and width of the lintels typically range from 100mm to 250mm, while the thickness can range from 6mm to 15mm. These dimensions ensure that the lintels can effectively support the loads while maintaining structural integrity.

Standard load-bearing capacities

Each standard steel lintel size comes with a specified load-bearing capacity. This capacity is typically measured in kilonewtons (kN) and indicates the maximum load that the lintel can safely support without any structural issues. The load-bearing capacity of standard steel lintels can range from 10kN to 100kN, depending on the size and design.

4. Choosing the right steel lintel size

Calculating load requirements

To choose the right steel lintel size, it is crucial to calculate the load requirements accurately. This involves considering the weight of the materials being supported, such as brickwork or concrete, as well as any additional live loads. The load requirements can be calculated with the help of structural engineers or professionals experienced in the field.

Determining span length

The span length is another critical factor in selecting the appropriate steel lintel size. The longer the span, the larger and stronger the lintel needs to be to ensure adequate support. Determining the accurate span length is essential to avoid any structural issues and ensure the long-term stability of the building.

Considering architectural requirements

In addition to the load requirements and span length, it is important to consider the architectural requirements of the building. The steel lintels should be selected to align with the desired architectural features, such as window size, shape, and overall aesthetic appeal. Balancing the structural and architectural requirements is essential in choosing the right steel lintel size.

Consulting with structural engineers or professionals

It is highly recommended to consult with structural engineers or professionals specialized in steel lintel sizing before making a final decision. They have the expertise and knowledge to evaluate the specific requirements of the project and recommend the most suitable steel lintel size. Their input can ensure the safety, durability, and efficiency of the construction project.

5. Custom steel lintel sizes

When and why custom sizes are required

In some cases, standard steel lintel sizes may not meet the specific requirements of a construction project. This can occur when dealing with unique architectural designs, non-standard openings, or unusual load requirements. In such situations, custom steel lintel sizes need to be ordered to address the specific needs of the project.

Considerations for ordering custom steel lintels

When ordering custom steel lintel sizes, several considerations need to be taken into account. These include accurately measuring the dimensions, ensuring compliance with building codes and regulations, and considering factors such as the required load-bearing capacity and span length. It is essential to work closely with manufacturers or suppliers who specialize in custom steel lintels to ensure that the dimensions and specifications are met accurately.

Benefits and drawbacks of custom steel lintels

Custom steel lintels offer several benefits, including tailored solutions for unique architectural designs and non-standard openings. They can provide the necessary support while maintaining the desired aesthetic appeal. However, custom steel lintels may also have drawbacks, such as longer lead times and potentially higher costs compared to standard sizes. Proper planning and coordination are necessary to mitigate any potential drawbacks.

6. How to measure for steel lintel sizes

Measuring the span

To measure for steel lintel sizes, start by measuring the span length accurately. This involves measuring the distance between the inner faces of the supporting walls or columns. It is important to account for any potential variations or irregularities in the opening dimensions to ensure the lintel fits properly.

Identifying the required load-bearing capacity

Once the span length is known, it is necessary to identify the required load-bearing capacity. This can be determined by considering the weight of the materials being supported and any additional live loads. It is crucial to ensure that the chosen steel lintel size can adequately support the anticipated loads.

Accounting for additional factors (e.g., brickwork, insulation, etc.)

In addition to the span length and load-bearing capacity, other factors should be considered when measuring for steel lintel sizes. These factors include the thickness of the surrounding brickwork, the presence of insulation, and any other materials or structural components that may impact the size and installation of the lintel. Accounting for these factors ensures a proper fit and optimal performance of the steel lintel.

7. Common applications of steel lintels

Residential buildings

Steel lintels find extensive use in residential buildings, particularly for supporting door and window openings. They provide reliable support to the masonry or brickwork above the openings and help maintain the structural integrity of the building. Steel lintels ensure the proper distribution of the load, preventing any sagging or structural issues.

Commercial buildings

In commercial buildings, steel lintels are commonly used to support larger openings, such as storefront windows and entranceways. These lintels can span significant distances and accommodate heavier loads. The strength and durability of steel lintels make them an ideal choice for commercial applications where robust structural support is vital.

Industrial structures

Industrial structures, such as warehouses and factories, often have unique requirements in terms of span lengths and load capacities. Steel lintels play a crucial role in supporting the expansive openings required for loading docks, large entranceways, and industrial equipment access points. They provide the necessary strength and stability for these demanding applications.

Infrastructure projects

Steel lintels are also essential components in infrastructure projects, such as bridges and tunnels. These critical structures require heavy-duty support systems, and steel lintels provide the necessary strength and load-bearing capacity. They help distribute the weight of the infrastructure and ensure its long-term stability and safety.

8. Advantages of using steel lintels

Strength and durability

One of the primary advantages of using steel lintels is their exceptional strength and durability. Steel is a robust material that can withstand heavy loads and resist deformation. Steel lintels are capable of providing reliable support for many years, ensuring the long-term structural integrity of the building.

Flexibility in design

Steel lintels offer flexibility in design, allowing for various architectural possibilities. They can be fabricated in different sizes and shapes to accommodate unique openings or architectural features. This flexibility enables architects and designers to create aesthetically pleasing designs while maintaining structural integrity.

Ease of installation

Installing steel lintels is relatively straightforward, making them a convenient choice for builders and contractors. The standardized sizes and well-defined load-bearing capacities simplify the installation process. Additionally, steel lintels can be easily adjusted or modified on-site if necessary, allowing for swift adjustments during construction.

Cost-effectiveness

Considering their strength and durability, steel lintels offer cost-effectiveness compared to alternative materials. They have a long lifespan, requiring minimal maintenance or replacement costs over time. Additionally, the ease of installation and availability of standardized sizes contribute to cost savings during the construction process.

Resistance to fire and pests

Steel lintels are highly resistant to fire, making them a reliable choice for fireproofing a building. In the event of a fire, steel lintels can withstand high temperatures, maintaining their structural integrity and preventing the spread of the fire. Moreover, steel lintels are not susceptible to pests, such as termites, ensuring the long-term stability of the structure.

9. Challenges and considerations in steel lintel sizing

Variances in building codes and regulations

One of the challenges in steel lintel sizing is the variances in building codes and regulations across regions. It is essential to ensure compliance with the specific requirements and standards of the area where the construction is taking place. Failure to comply with the regulations can lead to safety issues and legal complications.

Weight limitations

Steel lintels also have weight limitations that need to be considered during sizing. The supporting structure, such as the walls or columns, must have adequate capacity to bear the weight of the lintel. Additionally, the lintel size should not exceed the load-bearing capacity of the surrounding materials and components.

Compatibility with other construction materials

Steel lintels should be compatible with other construction materials, such as masonry or brickwork. The size and design of the lintels need to align with the specific requirements of these materials to ensure a seamless integration and optimal performance. Compatibility considerations are crucial to prevent any structural issues or damage to the surrounding components.

Thermal bridging and energy efficiency

Steel lintels can create thermal bridging, which can negatively affect the energy efficiency of a building. Thermal bridging occurs when a highly conductive material, such as steel, forms a direct pathway for heat to escape or enter the building. It is essential to consider thermal insulation measures to minimize thermal bridging when designing and sizing steel lintels.

10. Maintenance and care for steel lintels

Regular inspection and maintenance

Like any structural component, steel lintels require regular inspection and maintenance to ensure their long-term performance. Regular inspections should be conducted to check for any signs of structural damage, such as corrosion, cracks, or deformations. Any identified issues should be addressed promptly to prevent further deterioration.

Cleaning and corrosion prevention

To maintain the integrity of steel lintels, proper cleaning and corrosion prevention measures should be implemented. Regular cleaning, using appropriate non-abrasive methods, removes any dirt or debris that can contribute to corrosion. Applying suitable protective coatings or treatments can help mitigate the risk of corrosion caused by moisture or environmental factors.

Repair and replacement considerations

If any signs of significant structural damage or deterioration are detected in steel lintels, repair or replacement may be necessary. It is crucial to consult with professionals experienced in steel lintel repair to assess the severity of the damage and recommend appropriate remedies. Prompt action ensures the continued performance and safety of the building.

In conclusion, steel lintels are essential components in construction, providing support and stability to buildings. The appropriate steel lintel size is determined by factors such as load-bearing capacity, span length, building regulations, construction type, and design considerations. Standard sizes are readily available in the market, but custom sizes may be required to meet unique requirements. Accurate measurement, consideration of load requirements, and architectural factors are crucial in selecting the right size. Steel lintels offer various advantages, including strength, flexibility, ease of installation, cost-effectiveness, and resistance to fire and pests. However, challenges such as building regulations, weight limitations, compatibility with other materials, and thermal bridging need to be considered. Regular maintenance, cleaning, and prompt repair or replacement contribute to the longevity and performance of steel lintels in the construction industry.